CHO Transient Production (TunaCHO® Process)

CHO cells have been the workhorse for protein and antibody manufacturing. The major advantages of CHO include robust growth, hardiness in suspension culture, stellar protein production and secretion, and a long track record. The biggest drawback of CHO is that the cells are hard to transfect. As such, CHO cells have been primarily used for CHO stable production, not transient.

TunaCHO® technology platform solves the technical problem of low transient transfection efficiency. We are able to achieve a production yield greater than 1 gram per liter in shake flasks. We further have shown consistent PTM profiles between TunaCHO® and CHO-GSN®. Based on yields, Curia favors CHO over HEK293 as a transient protein production platform.

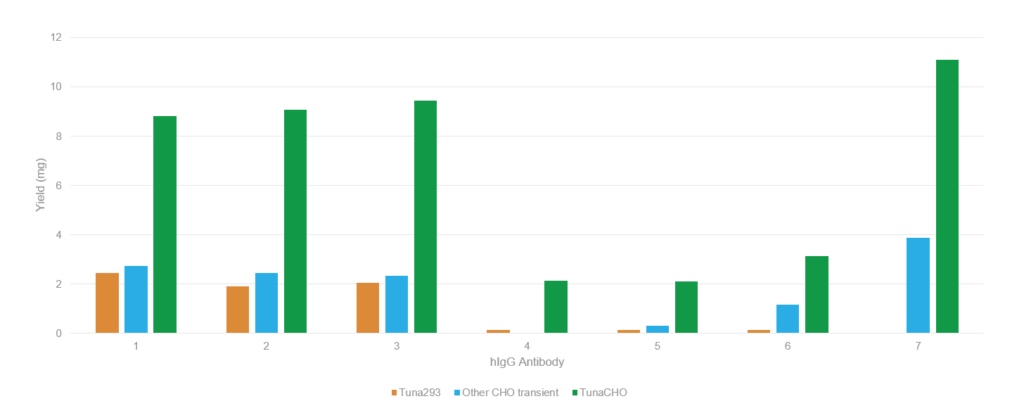

Below is a graph of typical yields between our Tuna293 transient production platform, our TunaCHO® expression system, and other CHO transient expression system to show the difference in yields.

Recombinant antibody expression with TunaCHO® process is significantly higher than HEK293 cells.